Photogrammetry enables precise digital inspection – but what is it, exactly?

Structural inspection, at periodic intervals, is of major importance to ensure the integrity of structures: their functionality, safety, and longevity. Thoroughly inspecting structures manually can be a painstaking affair, especially when it concerns a structure of significant magnitude. Using photogrammetry, structures such as bridges, tunnels, and dams can be modelled into a so-called digital twin, textured in high resolution, by virtue of employing the use of simple photographic images. These images are later processed in high definition using Artificial Intelligence (AI) to identify, analyze, and document structural damages with never seen before levels of detail – and at scale.

The Science Behind Photogrammetry

The term “photogrammetry” is a combination of three Greek words, “photos” (light), “gramma” (to draw or write), and “metron” (to measure). Together, the term refers to the science of making measurements by extracting feasible and reliable data from photographic images. This technique involves taking images to get results in the form of a map, a drawing, a measurement, or a 3D-model of some real-world object or scene. Even though the process requires solving lengthy mathematical equations to find coherence between coordinate systems, the science behind it, in reality, is fairly simple.

A general idea can be derived from stereoscopy, meaning “seeing in stereo”. At some point in our lives, we realize that it is not possible to see in 3D with the use of just one eye. Give it a shot if you never have – or need a reminder. Close or cover one of your eyes and try to grab a cup of coffee. Or, better yet, try pouring water into a glass. Not as easy as you’re used to, right?

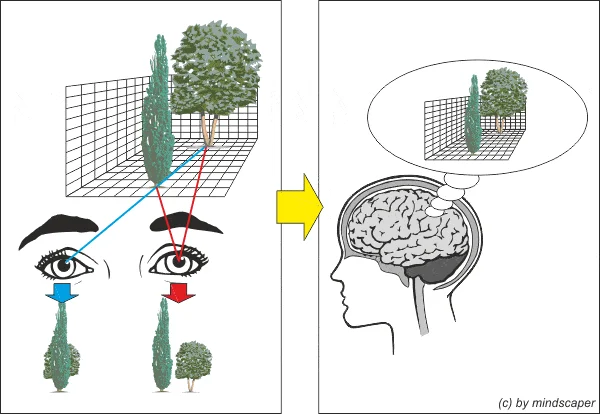

Our eyes each basically operate like cameras with a fixed distance between them. They create 2D-images of our surroundings to form two very similar but also slightly different perspectives. These slight variations in perspective make all the difference. Objects that are closer to our face (the point where our perspective is formed by our eyes) create bigger “perspective” differences in the two separate images created by both our eyes than objects that are further away. This information is processed in our central processing unit, the brain, to create a scene in 3D for more accurate orientation and perception, alerting us unwanted outcomes, for example, such as not spilling water on the table. The same principle applies when processing data through photogrammetry. Just replace your eyes with a camera, and your brain with a computer.

Deriving geometric relationships from differences in perspective

(https://lens-shutter.net/stereo-kurz-erklaert/)

But remember that at least 80% of the image contains data showing the same scene, so don’t move too far away with a second camera. Subsequently, a third or a fourth, or a fifth camera can be used to refine this data. By taking scenes from all these cameras, a 3D-model of your structure can be created. Automatically.

A Lot of Cameras – Sounds Like a Lot of Investment!

The beauty of photogrammetry is that the same camera can be used multiple times, as long as the object being captured does not change its position. Welcome to the exciting world of photogrammetry! The technique does not depend on taking images simultaneously. With the advent of Unmanned Aerial Vehicles (UAVs) or drones in the last decade, it has become convenient and economical to use them as “camera carriers” for taking high-quality images from specific viewpoints, many of which would have proven inaccessible, previously. Sounds novel, doesn’t it? However, if you think that strapping a camera onto a flying object is a recent idea, think again…

Photography Pigeons at work (ca. World War I)

By Bundesarchiv: o.Ang.derivative work: Hans Adler (talk), CC BY-SA 3.0 de, https://commons.wikimedia.org/w/index.php?curid=7163150

What Exactly are “High-Quality Images”?

Science apart, let’s get a better understanding of images themselves. To derive relevant data from photographs, the image in itself needs to be of sufficient quality. Parameters such as resolution (pixels – or, indeed, megapixels), brightness, aperture, sharpness, and color must meet the required criteria to be used for photogrammetry. Here, the philosophy of “more is always better” does not apply. Sometimes, using fewer images or camera positions can create the better results. The same goes for resolution; too many megapixels can mean slower processing times by creating larger files without adding enough value. In other words, there is a sweet spot for optimum results when it comes to resolutions. Going beyond it will stop adding value – and simply add data.

Requirements can vary depending on project needs. Factors that can affect high-quality results include different sensor sizes, focal lengths, and object distances. A common denominator is the definition of a parameter called “GSD” or “Ground Sampling Distance”. GSD indicates how much area of an object is captured in a single pixel. For example, a GSD of 1mm means that 1 pixel in the image corresponds to 1mm x 1mm (= 1mm²) in reality.

How Does Photogrammetry Help to Improve Safety?

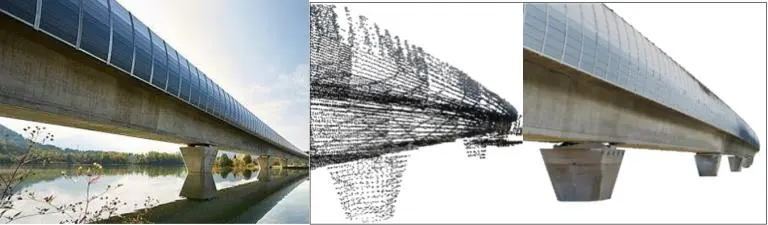

In the field of structural inspections, photogrammetry provides exact information about the current condition of the structures by creating 3D geometrical along with higher-resolution textural information. Results from photogrammetric processing can be so-called “point clouds” in various densities, textured or untextured meshes, or even projected ortho-mosaics. The output can be further processed as inputs for Building Information Management (BIM), and for creating a precise base for lifecycle analyses, as well as predictive maintenance to keep infrastructure safe.

Employing this technology means that locations that are difficult to reach that typically make structural inspection more prone to risk can be done from the comfort of an office chair. Inspection experts can forego the requirement of hanging from a bridge in the Alps and instead focus on securing the safety of others.

From an image (left), to point cloud (middle) and textured digital 3D twin (right)

(From the document “Bauwerksprüfung 4.0 with STRUCINSPECT”, pages 2 and 3)

Is Photogrammetry a Key Factor in the Future of Digital Inspections?

Yes, it most certainly is! Photogrammetry provides seamless documentation of the surface condition of a complete infrastructural element along with the generation of organized, structured data that can be further processed, analyzed, and stored for future references. Moreover, objective comparisons with previous data can be more easily performed for improved asset management over time. This simplifies and streamlines the entire process of structural inspection.

Are you looking to simplify your structural inspections?